Research Projects

Some of the projects that I have had the pleasure to participate:

In-situ Refractory Drying Observation

2021-...

The water withdraw from refractory castables involves several mechanisms that take place at multiple scales within this complex heterogeneous porous medium. This project aims to use neutron and x-ray tomography to assess in-situ how the water is transported during the non-isothermal drying.

Refractory Drying Simulation

2019-...

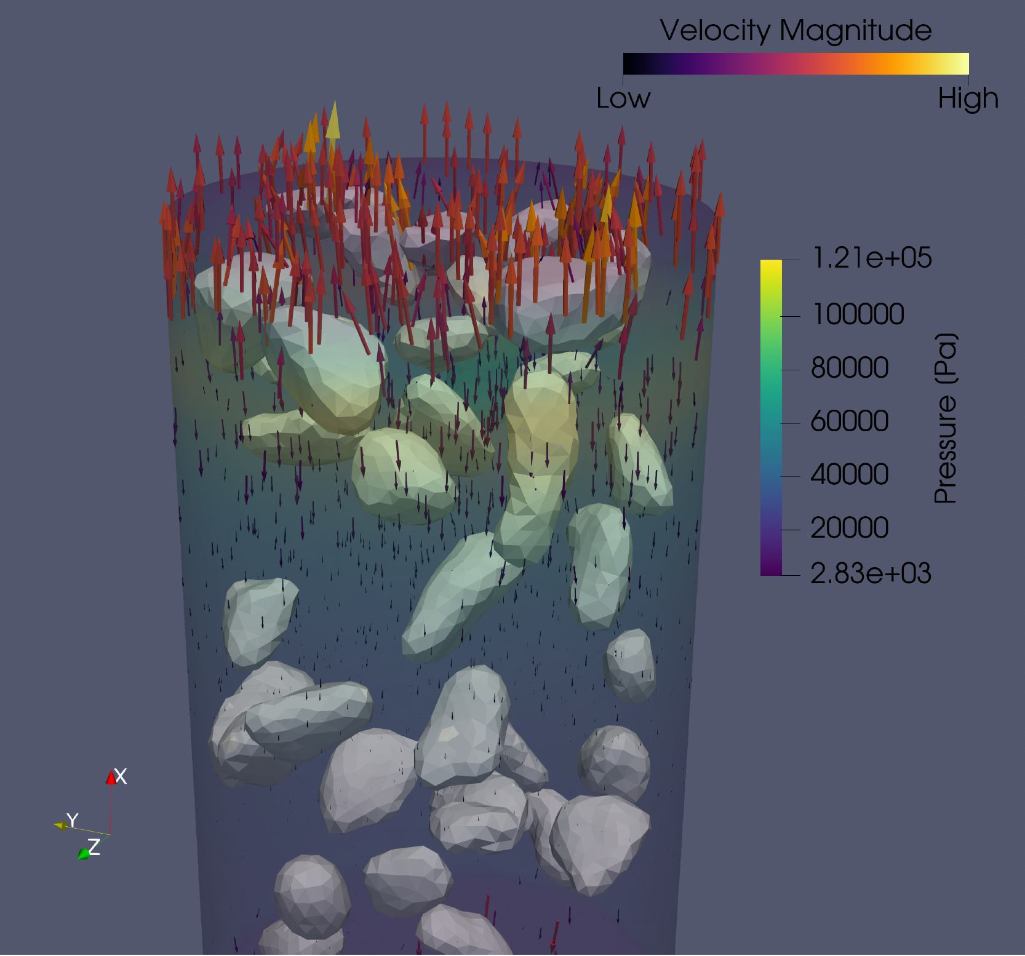

The drying of refractory castables is the longest step during their installation within the industrial scenario. Heat-up protocols that balance the risk of explosive spalling and the reduction of the long production halts are critical for this application. This project proposes the simulation of the drying process of refractory castables based on the theory of partially saturated porous media.

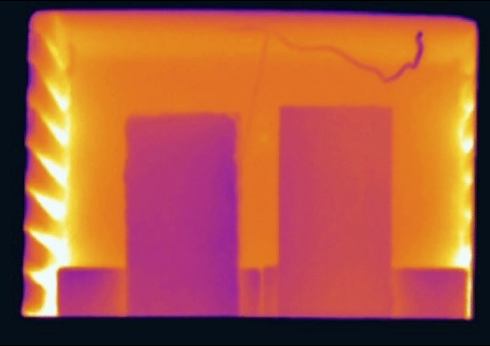

Microwave Refractory Drying Feasability

2021-2023

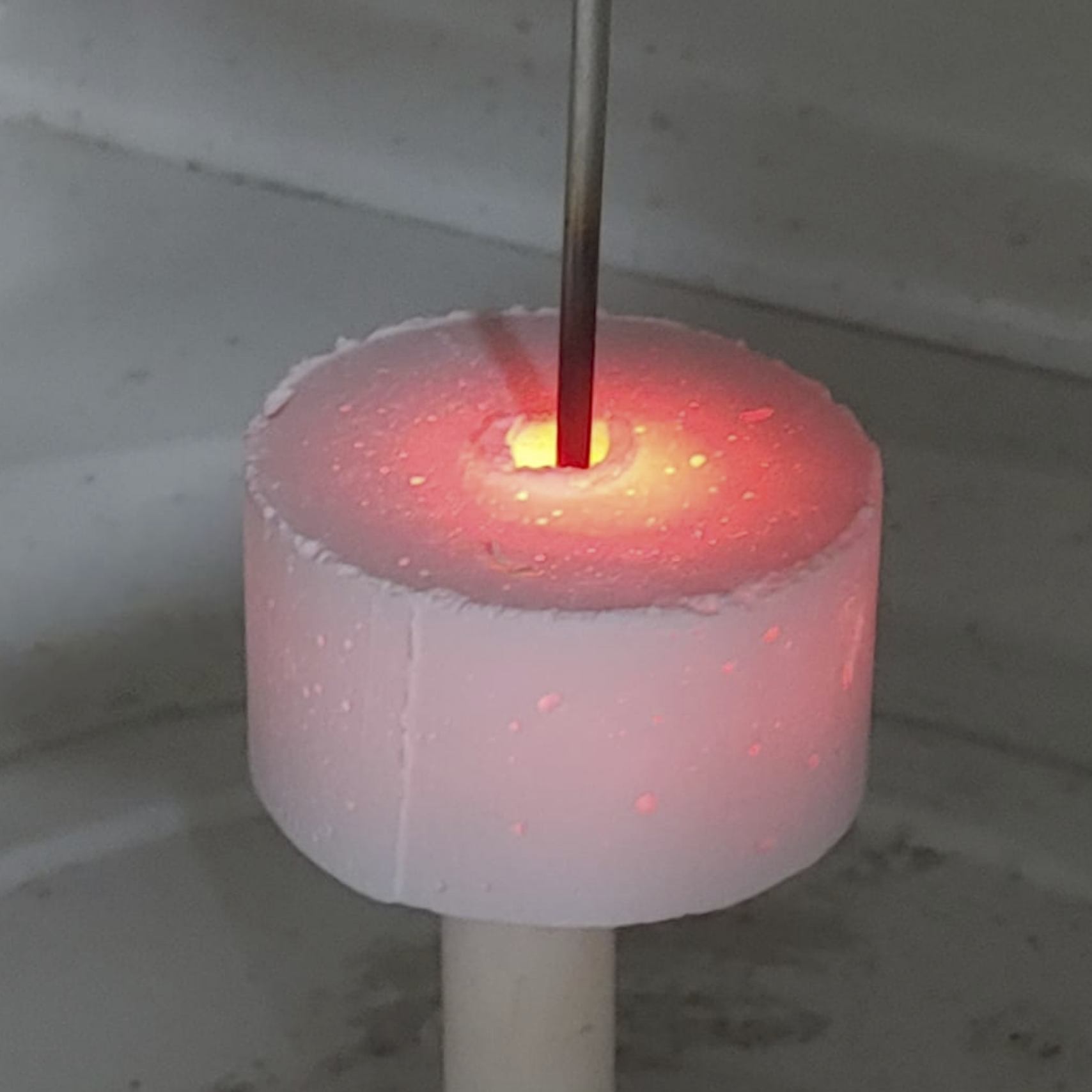

Aiming to reduce the drying process time and to maintain the process safe, the use of microwave heating was explored as an alternative to the traditional methods based in natural gas burners. The completely different physics of heat transport in these two scenarios leads to opposite thermal gradients. The preparation of a microwave baesd thermogravimetry showed that the mass loss peaks observed during the drying were shifted to smaller temperatures.

Alumina Phase Conversion

2014-2015

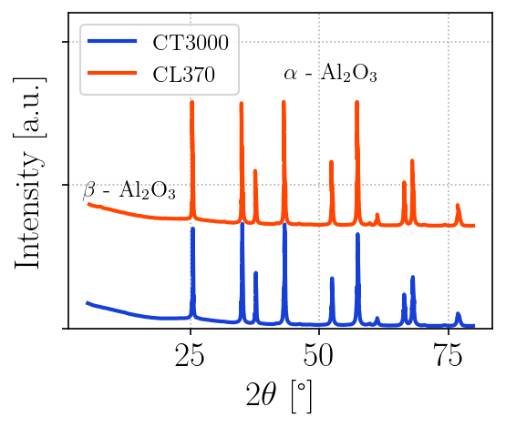

In this study the use of Aluminum Fluoride as a mineralizing agent for the transformation of transition aluminas to α-alumina was considered. Through the use of this additive, conversion temperatures were reduced, lowering the consumption of fossil fuels and the cost of the process. Various experimental assays were employed to characterize the obtained products, such as particle size distribution, mass spectrometry, X-ray diffraction, and DSC.

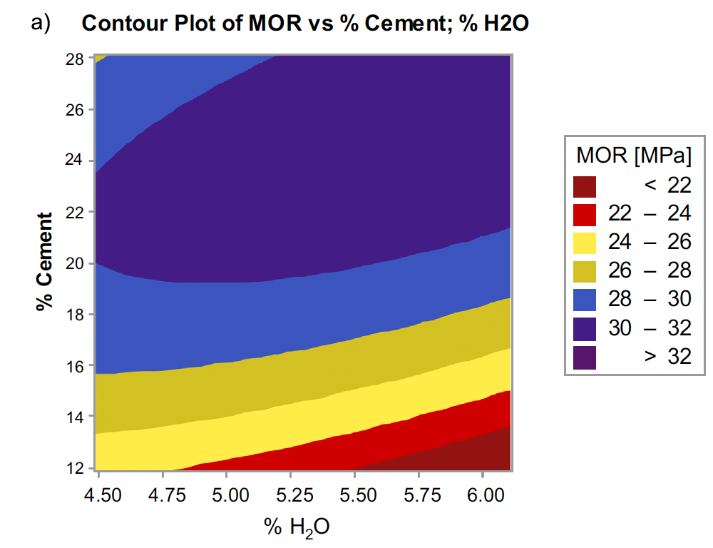

Design of Experiments Feasibility in Refractory Castables

2015-2016

The use of Design of Experiments (DOE) is an essential approach for conducting systematic and reproducible studies. Its application in the field of refractory ceramic materials is limited, and this project aimed to identify if such a tool could be used to extract information from sets of experiments already conducted. It was found that the high variability and complexity of the system addressed hindered its effectiveness

Data Minning on Refractories Research

2015-2016

In this project, the aim was to employ data mining techniques combined with graph theory to analyze the last 21 years of scientific production in the field of refractory ceramics. The study assessed geographical aspects and international partnerships, encompassing research institutions as well as major companies in the field.

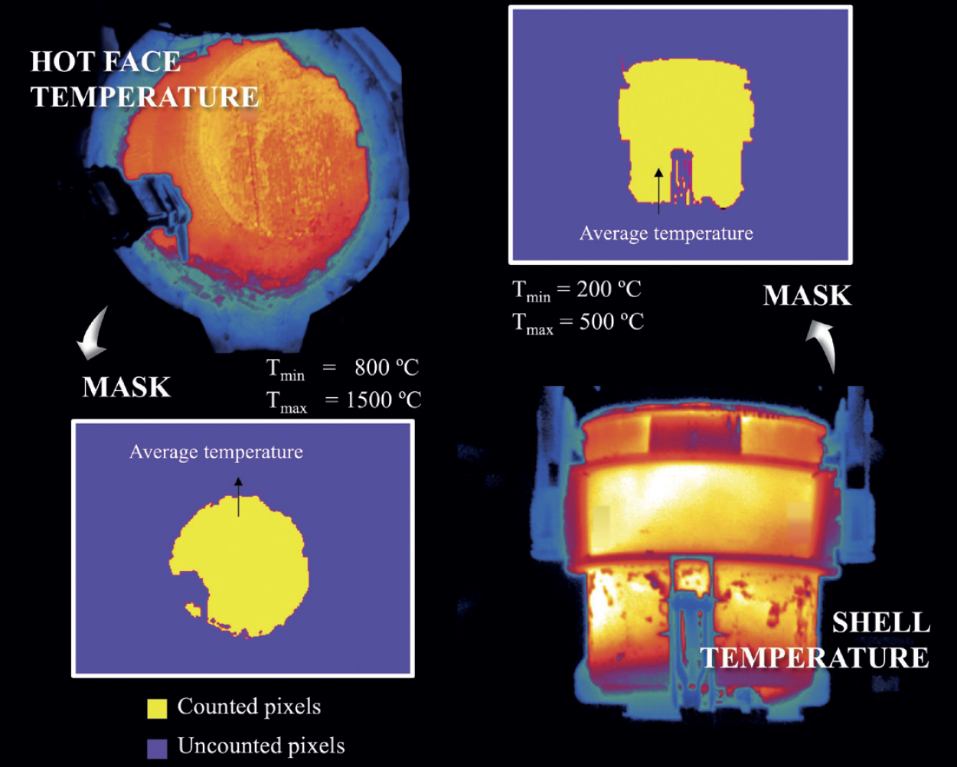

Thermal Management of Steel Ladles

2016-2018

The use of computational tools for simulating diverse scenarios in industrial applications enables the proposal of various innovative designs, assessments of potential economic gains, and reductions in environmental impacts. This current project aimed to analyze the steelmaking process, specifically the steel ladle, and propose novel solutions for its thermal management through the use of numerical simulations.

High Emissivity Coatings

2016-2019

The goal of this project was to reduce costs in high-temperature processes and enhance the performance of refractory materials as thermal insulators. The study focuses on investigating the fundamentals of thermal energy transport via radiation to comprehend the benefits of high emissivity coatings and compare them with high reflectance coatings.